Are Plastic Gear Racks Suitable for Packaging Lines?

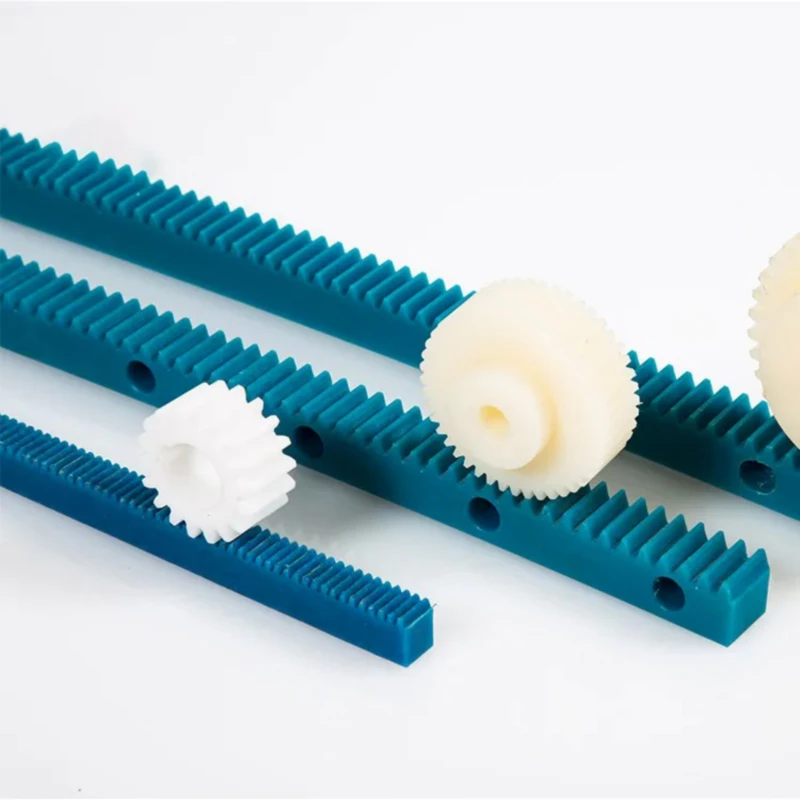

A Plastic Gear Rack is a type of gear rack made from plastic materials, designed to transmit power and motion. These gear racks are commonly used in various industrial applications due to their lightweight, corrosion resistance, and cost-effectiveness.

Structure and Materials

Composition of Plastic Rack

The basic structure of a Plastic Gear Rack consists of a series of teeth and gaps, which interlock with a gear to transmit power and motion. The design of the rack and the profile of the teeth are crucial in ensuring efficient force transmission and motion control.

Commonly Used Plastic Materials

Common plastic materials used in the manufacturing of these gear racks include polyamide (PA), polyethylene (PE), and polypropylene (PP), among others.

Advantages

Lightweight and Corrosion Resistance

Plastic Gear Racks are lightweight, making them easy to handle and install. Their natural resistance to corrosion makes them ideal for environments where metal racks would degrade quickly.

Low Noise and Low Friction

These gear racks operate quietly due to the low noise generation and reduced friction between moving parts.

Cost-Effective and Easy to Process

Plastic Gear Racks are cost-effective to produce and are easier to process compared to metal racks, which require more complex manufacturing methods.

Design Flexibility

The flexibility in design allows for custom shapes and sizes to meet specific application needs.

Resistance to Chemicals and Moisture

Their resistance to a wide range of chemicals and moisture makes them suitable for harsh industrial environments.

Reduced Wear on Other Components

Plastic Gear Racks cause less wear on mating components, extending the overall lifespan of the machinery.

Applications

Automation and Robotics

Plastic Gear Racks are widely used in automation and robotics systems for precise motion control and power transmission. They are utilized in robotic arms, gantry systems, linear actuators, and other automated machinery.

Electric Tools and Appliances

These gear racks are employed in electric tools such as drills, saws, and sanders, where they help convert rotational motion into linear motion. They are also used in household appliances like mixers, blenders, and printers for smooth and efficient operation.

Transportation and Automotive

Plastic Gear Racks are utilized in various transportation and automotive applications. They can be found in steering systems, seat adjustment mechanisms, window regulators, and convertible tops, providing reliable and precise movement.

Medical Equipment

In the medical field, these gear racks are used in hospital beds, patient lifts, and adjustable tables. Their lightweight, corrosion-resistant, and low-noise properties make them suitable for healthcare settings.

Packaging and Material Handling

In packaging and material handling machinery, Plastic Gear Racks facilitate the movement of products along conveyor systems or for precise positioning in packaging operations.

Industrial Machinery

These gear racks are found in various industrial machinery, including CNC machines, cutting systems, textile machinery, and printing presses. Their low friction and wear properties contribute to smooth operation and reduced maintenance.

Agricultural Equipment

In agricultural machinery, such as crop harvesters, seeders, and irrigation systems, Plastic Gear Racks help in the efficient movement of components and ensure precise control in agricultural operations.

Recreation and Sports Equipment

These gear racks are used in recreational and sports equipment, such as exercise machines, bicycles, and golf carts, to convert rotational motion into linear motion for enhanced performance.

Renewable Energy Systems

Plastic Gear Racks are employed in renewable energy systems, including solar panel tracking systems and wind turbine pitch control mechanisms, to optimize energy generation and tracking capabilities.

Installation and Maintenance

Installation

1. Select Appropriate Installation Location: Choose a location that ensures optimal performance and ease of maintenance.

2. Alignment and Fixing: Properly align and secure the gear rack to avoid any misalignment issues.

3. Adjust Tension: Adjust the tension of the gear rack to ensure smooth operation.

Maintenance

1. Regular Cleaning: Keep the gear racks clean to prevent debris build-up that can affect performance.

2. Lubrication: Apply appropriate lubricants to reduce friction and wear.

3. Inspection and Replacement of Worn Parts: Regularly check for wear and replace components as needed.

4. Avoid Overloading and Improper Use: Ensure that the gear racks are not subjected to loads beyond their capacity.

5. Periodic Inspection and Maintenance of Other Related Components: Regularly inspect and maintain other components in the system to ensure optimal performance.

Choosing the Right Plastic Gear Rack

Load Capacity

Consider the load capacity of the gear rack to ensure it can handle the required forces without failure.

Gear Module

The gear module should be selected based on the desired gear ratio and application requirements.

Rack Length and Dimensions

Select the appropriate length and dimensions of the gear rack to fit the specific application.

Material Selection

Choose the plastic material based on the environmental conditions and performance requirements.

Accuracy Requirements

Ensure that the gear rack meets the necessary accuracy standards for the application.

Environmental Conditions

Consider the environmental conditions, such as temperature and humidity, to select a gear rack that can withstand these factors.

Manufacturer Reputation and Quality

Select a manufacturer with a good reputation and proven track record of producing high-quality gear racks.

Cost-Effectiveness

Balance the cost with the required performance and quality to ensure a cost-effective solution.

EVER POWER Company Overview

The company has more than 100 professional rack production equipment and testing equipment. The one-time processing length of the rack is 3000MM, the module range is M1-M30, British CP, American DP, etc., in order to better adapt to market changes. For high-end customers who demand high-precision racks, our company specially introduces rack milling machines and rack grinding machines imported from Germany. The precision of the racks produced by this equipment can reach (JIS2 level) DIN6n25 to meet various needs of the high-end market, with excellent products, affordable prices, and good service attitude, our products are exported to different countries such as Spain, the Netherlands, the United States, South Korea, Turkey, and Russia. At the same time, we sincerely hope to help customers develop new products and solve technical and quality problems. We are willing to meet the needs of users with high-quality products, fair prices, and perfect services. In short, we adhere to the principles of quality first, timely delivery, and credit first, treat every business partner sincerely, and wholeheartedly welcome friends from the business community to cooperate with us to develop together and create brilliance.

Besides, EVER POWER also offers other rack products such as Gear Rack For Door Opener, gear rack for elevator, rack and pinion steering, metric gear rack, etc. Customers are welcome to inquire about customized products. EVER POWER is a professional manufacturer of racks in China. Its products are mainly sold to hundreds of fixed suppliers such as domestic steel rolling mills, shipyards, precision machine tool factories, automation machinery factories and various distribution companies, and exported to Western Europe, the Middle East, and Southeast Asia. and other countries and regions. The developing EVER POWER currently has hundreds of employees, including many engineers, with fixed assets of 20 million yuan and an annual output value of 50 million yuan. It mainly produces 1 to 32 module standard racks, non-standard straight racks, helical racks, double-sided racks, cylindrical racks, and various inch racks, with an accuracy of up to 7