Can forged bevel gears be repaired or refurbished?

Introduction

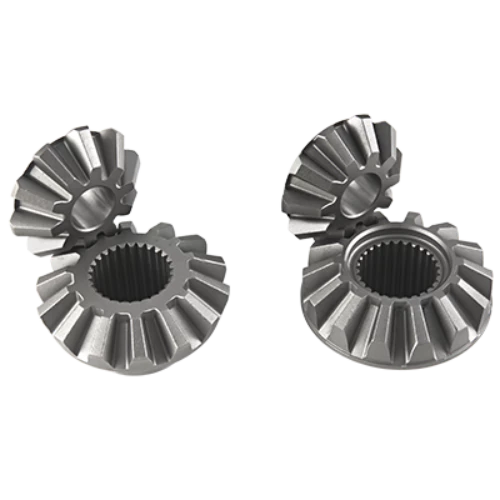

Forging bevel gears are a type of bevel gears that are manufactured through the forging process. Forging involves shaping metal through the application of localized compressive forces, typically using a die or hammer. In the case of bevel gears, the forging process is used to form the gear teeth and create the desired gear geometry.

Advantages of Forged Bevel Gears

- High Strength: Forged bevel gears are known for their exceptional strength, making them suitable for high-load applications.

- Improved Fatigue Resistance: The forging process enhances the fatigue resistance of bevel gears, ensuring their long-term durability.

- Precise Gear Tooth Geometry: Forging allows for the creation of precise gear tooth profiles, resulting in smoother and more efficient gear operation.

- Cost-Effectiveness: Despite their superior performance, forged bevel gears offer cost-effective solutions for various industries.

- Versatility in Material Selection: The forging process allows for the use of different materials, enabling tailored solutions for specific applications.

- Enhanced Structural Integrity: The forging process eliminates defects and enhances the structural integrity of bevel gears, improving their overall performance.

- Tailored Mechanical Properties: By controlling the forging process, bevel gears can be customized to possess specific mechanical properties, meeting the unique requirements of different applications.

- Reduced Lead Time: Forging bevel gears can be produced quickly, reducing lead time and ensuring timely delivery.

- Environmental Sustainability: The forging process is known for its minimal waste generation and energy consumption, making forged bevel gears an environmentally friendly choice.

Working Principle

Forging bevel gears operate based on the fundamental principles of gear mechanisms. They consist of two intersecting shafts, each with a conically shaped gear (bevel gear) mounted on it. The teeth of the bevel gears are designed to have a specific tooth profile, such as straight, spiral, or hypoid, depending on the application requirements.

When the input shaft rotates, the engagement of the teeth of the bevel gears causes a transfer of rotational motion and torque to the output shaft. The contact between the mating teeth ensures power transmission while maintaining proper alignment and smooth operation.

Applications

- Automotive Industry: Forged bevel gears are used in various automotive applications, such as steering systems, differentials, and transmissions.

- Industrial Machinery: They are also widely utilized in industrial machinery, including mining equipment, construction machinery, and metalworking machinery.

- Aerospace and Defense: Forged bevel gears play a crucial role in aerospace and defense applications, ensuring reliable and efficient performance.

- Renewable Energy: They are used in wind turbines and other renewable energy systems to convert rotational motion into electrical energy.

- Marine and Shipbuilding: Forged bevel gears are essential components in marine engines, propellers, and other shipbuilding applications.

- Agricultural Machinery: They are utilized in agricultural machinery like tractors and harvesters, enabling efficient operation in the field.

- Power Generation: Forged bevel gears are used in power plants and other energy generation facilities to transmit power between rotating components.

- Robotics and Automation: They are employed in robotics and automated systems, providing precise and reliable motion control.

Installation and Maintenance

Installation:

- Proper Alignment

- Lubrication

- Mounting Bolts

- Inspection

Maintenance:

- Lubrication

- Cleaning

- Inspection

- Replacements

- Gearbox Maintenance

- Load Monitoring

- Training and Expertise

- Record-Keeping

How to Select the Right Forging Bevel Gear

- Application Requirements: Consider the specific requirements of the application, such as load capacity, speed, and environmental conditions.

- Design and Specifications: Choose a forging bevel gear with the appropriate design and specifications to ensure compatibility and optimal performance.

- Material Selection: Select a material that suits the application's demands in terms of strength, durability, and resistance to wear and corrosion.

- Quality and Reliability: Prioritize gears from reputable manufacturers known for their quality and commitment to producing reliable products.

- Load-Carrying Capacity: Determine the gear's load-carrying capacity to ensure it can handle the required forces and torque.

- Efficiency and Performance: Evaluate the gear's efficiency and performance characteristics to ensure optimal operation.

- Customization and Adaptability: Consider the need for customized solutions and adaptability to specific application requirements.

- Cost Considerations: Assess the overall cost-effectiveness, taking into account initial investment, maintenance, and long-term performance.

Shaoxing Chaoli: A Reliable Manufacturer

Shaoxing Chaoli is a professional manufacturer of gears in China. With the aim of helping customers develop new products and solve technical and quality problems, we offer high-quality products, fair prices, and perfect services.

Our products are exported to different countries such as Spain, the Netherlands, the United States, South Korea, Turkey, and Russia. We adhere to the principles of quality first, timely delivery, and credit first. We treat every business partner sincerely and wholeheartedly welcome friends from the business community to cooperate with us and create brilliance together.

Shaoxing Chaoli also offers other gear products such as Worm Gear, Spiral Bevel Gear, Helical Gear, Spur Gear, Plastic Gear, and Metric Gear Rack. Customers are welcome to inquire about customized products.

Shaoxing Chaoli has a complete set of strict quality management systems and is equipped with precision measuring instruments like optical projectors and 16 full-process production monitoring systems.

Our company has considerable competitiveness in the industry, serving domestic steel rolling mills, shipyards, precision machine tool factories, automation machinery factories, and various distribution companies. Our products are also exported to Western Europe, the Middle East, Southeast Asia, and other countries and regions.

With hundreds of employees, including many engineers, fixed assets of 20 million yuan, and an annual output value of 50 million yuan, Shaoxing Chaoli is dedicated to providing high-quality gears and ensuring customer satisfaction.