Can Plastic Gear Racks Be Used in Material Handling Systems?

Plastic Gear Rack is a type of gear rack made from plastic materials, used to transmit power and motion. This blog will delve into the viability of using plastic gear racks in material handling systems, exploring their structure, benefits, applications, installation, maintenance, and selection criteria.

Structure and Materials

A. Composition of Plastic Rack

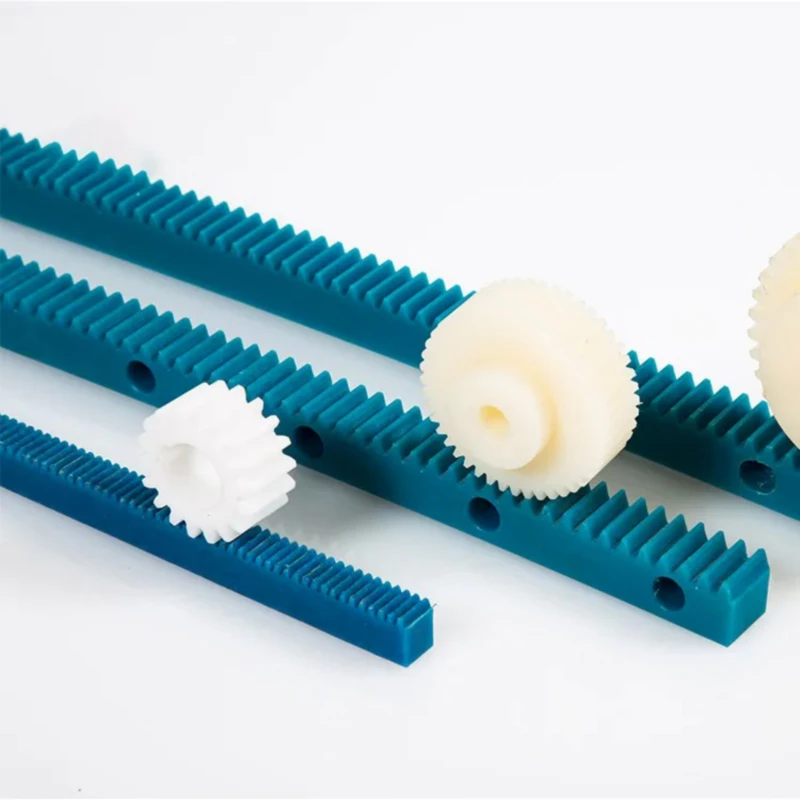

The basic structure of a Plastic Gear Rack consists of a series of teeth and gaps. The design of the rack and the tooth profile plays a crucial role in the efficient transmission of force and motion. Understanding the intricacies of these components can greatly impact performance and lifespan.

B. Commonly Used Plastic Materials

Plastic Gear Racks are typically made from materials like polyamide (PA), polyethylene (PE), and polypropylene (PP). Each material offers unique properties, such as strength, flexibility, and resistance to wear and tear.

Advantages

1. Lightweight and Corrosion Resistance

Plastic Gear Racks are lightweight, which makes them easier to handle and install. Their resistance to corrosion ensures longevity, even in harsh environments.

2. Low Noise and Low Friction

These racks operate quietly and with minimal friction, reducing wear and tear on other components and enhancing overall system efficiency.

3. Cost-Effective and Easy to Process

The production of plastic gear racks is cost-effective, and they are easy to process, which allows for quicker turnaround times and lower manufacturing costs.

4. Design Flexibility

Plastic materials offer flexibility in design, allowing for complex shapes and sizes that may not be feasible with metal counterparts.

5. Resistance to Chemicals and Moisture

Plastic Gear Racks are resistant to various chemicals and moisture, making them suitable for a wide range of industrial applications.

6. Reduced Wear on Other Components

The low friction and smooth operation of plastic gear racks contribute to reduced wear on interacting components, prolonging the lifespan of the entire system.

Applications

Automation and Robotics

Plastic Gear Racks are extensively used in automation and robotics systems for precise motion control and power transmission. They are integral to the operation of robotic arms, gantry systems, linear actuators, and other automated machinery.

Electric Tools and Appliances

In electric tools like drills, saws, and sanders, plastic gear racks convert rotational motion into linear motion. Household appliances such as mixers, blenders, and printers also rely on them for smooth and efficient operation.

Transportation and Automotive

Plastic Gear Racks are employed in various transportation and automotive applications, including steering systems, seat adjustment mechanisms, window regulators, and convertible tops, ensuring reliable and precise movement.

Medical Equipment

In healthcare settings, plastic gear racks are used in equipment like hospital beds, patient lifts, and adjustable tables due to their lightweight, corrosion-resistant, and low-noise properties.

Packaging and Material Handling

Plastic Gear Racks facilitate the movement of products along conveyor systems or precise positioning in packaging operations, making them essential in packaging and material handling machinery.

Industrial Machinery

These racks are vital in various industrial machinery, including CNC machines, cutting systems, textile machinery, and printing presses, contributing to smooth operation and reduced maintenance.

Agricultural Equipment

In agricultural machinery, such as crop harvesters, seeders, and irrigation systems, plastic gear racks ensure efficient movement and precise control of components, enhancing agricultural operations.

Recreation and Sports Equipment

Plastic Gear Racks are used in recreational and sports equipment, including exercise machines, bicycles, and golf carts, to convert rotational motion into linear motion for improved performance.

Renewable Energy Systems

In renewable energy systems, such as solar panel tracking systems and wind turbine pitch control mechanisms, plastic gear racks optimize energy generation and tracking capabilities.

Installation and Maintenance

Installation

1. Choose the Right Installation Position

Selecting the appropriate installation position ensures optimal performance and longevity of the plastic gear rack.

2. Alignment and Fixation

Proper alignment and fixation are crucial to prevent operational issues and ensure smooth motion transmission.

3. Adjust Tension

Adjusting the tension of the gear rack is essential for maintaining optimal performance and preventing premature wear.

Maintenance

1. Regular Cleaning

Periodic cleaning helps remove debris and contaminants that can affect the performance of the plastic gear rack.

2. Lubrication

Regular lubrication reduces friction and wear, extending the lifespan of the gear rack and associated components.

3. Inspection and Replacement of Worn Parts

Routine inspection and timely replacement of worn parts ensure the continued efficiency and reliability of the system.

4. Avoid Overloading and Misuse

Preventing overloading and improper use is vital for maintaining the integrity and performance of the plastic gear rack.

5. Regular Inspection and Maintenance of Related Components

Consistent inspection and maintenance of related components help identify potential issues early and prevent system failures.

How to Choose the Right Plastic Gear Rack

1. Load Capacity

Assessing the load capacity requirements ensures the selected plastic gear rack can handle the operational stresses.

2. Gear Module

Choosing the appropriate gear module is essential for compatibility and efficient power transmission.

3. Rack Length and Dimensions

Considering the length and dimensions of the gear rack ensures it fits the intended application and space constraints.

4. Material Selection

Selecting the right material based on application requirements enhances performance and durability.

5. Precision Requirements

Meeting precision requirements is crucial for applications requiring high accuracy and consistent performance.

6. Environmental Conditions

Considering environmental conditions, such as temperature and exposure to chemicals, ensures the chosen gear rack performs optimally.

7. Manufacturer Reputation and Quality

Choosing a reputable manufacturer with a track record of quality ensures reliability and performance of the plastic gear rack.

8. Cost-Effectiveness

Evaluating the cost-effectiveness of the gear rack helps balance performance and budget considerations.

EVER POWER Company Overview

The company boasts over 100 professional rack production equipment and testing instruments, with the ability to process racks up to 3000MM in length. The module range spans from M1 to M30, including British CP and American DP systems, catering to market demands. For high-end clients requiring precision racks, EVER POWER has invested in German-imported rack milling and grinding machines, achieving precision levels up to JIS2 (DIN6n25). Our products are competitively priced and exported to countries like Spain, the Netherlands, the USA, South Korea, Turkey, and Russia. We are committed to helping customers develop new products and resolve technical issues, upholding the principles of quality, timely delivery, and creditworthiness. Besides, EVER POWER offers specialized products such as Gear Rack For Door Opener, gear rack for elevators, rack and pinion steering, and metric gear racks. Our products serve various industries, including steel mills, shipyards, precision machine tool factories, and more, with an annual output value of 50 million yuan. The company employs hundreds of staff, including engineers, and maintains a strict quality management system, equipped with precision measuring instruments and automated production lines. EVER POWER remains a competitive force in the industry.