Forging Bevel Gear Load Capacity Analysis

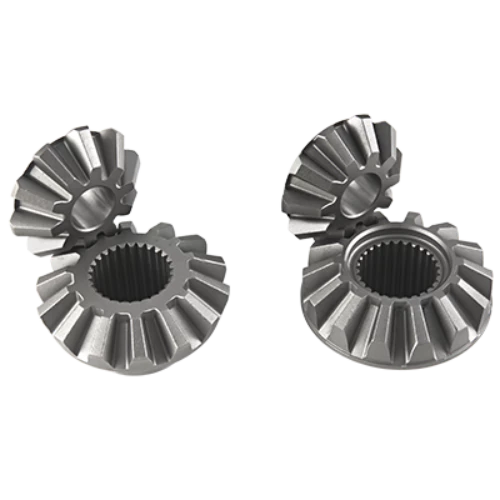

Forging bevel gears are a type of bevel gears that are manufactured through the forging process. Forging involves shaping metal through the application of localized compressive forces, typically using a die or hammer. In the case of bevel gears, the forging process is used to form the gear teeth and create the desired gear geometry.

Advantages of Forging Bevel Gears

- High Strength: The forging process enhances the strength and durability of bevel gears, making them suitable for heavy-duty applications.

- Improved Fatigue Resistance: Bevel gears produced through forging have better fatigue resistance, allowing them to withstand repeated loading without failure.

- Precise Gear Tooth Geometry: Forging ensures precise gear tooth profile and geometry, resulting in smooth and efficient gear operation.

- Cost-Effectiveness: Despite their high strength and performance, forging bevel gears offer cost-effective solutions for various industries.

- Versatility in Material Selection: The forging process allows the use of various materials, including steel, stainless steel, and alloy, based on specific application requirements.

- Enhanced Structural Integrity: The forging process eliminates defects and enhances the structural integrity of bevel gears, ensuring reliable and long-lasting performance.

- Tailored Mechanical Properties: By controlling the forging process parameters, bevel gears can be tailored to have specific mechanical properties, such as hardness and toughness.

- Reduced Lead Time: The forging process enables faster production of bevel gears compared to other manufacturing methods.

- Environmental Sustainability: Forging is a sustainable manufacturing process that minimizes waste and energy consumption.

Working Principles of Forging Bevel Gears

Forging bevel gears operate based on the fundamental principles of gear mechanisms. They consist of two intersecting shafts, each with a conically shaped gear (bevel gear) mounted on it. The teeth of the bevel gears are designed to have a specific tooth profile, such as straight, spiral, or hypoid, depending on the application requirements.

When the input shaft rotates, the engagement of the teeth of the bevel gears causes a transfer of rotational motion and torque to the output shaft. The contact between the mating teeth ensures power transmission while maintaining proper alignment and smooth operation.

Applications of Forging Bevel Gears

Forging bevel gears find applications in various industries, including:

- Automotive Industry: Forging bevel gears are used in automotive transmissions, differential systems, and steering mechanisms.

- Industrial Machinery: These gears are essential components in industrial machinery, such as machine tools, conveyors, and printing presses.

- Aerospace and Defense: Forging bevel gears are utilized in aircraft engines, helicopter transmissions, and military vehicles.

- Renewable Energy: Wind turbines and solar power systems require bevel gears for power transmission and angle adjustment.

- Marine and Shipbuilding: Forging bevel gears are used in marine propulsion systems, steering gears, and winches.

- Agricultural Machinery: These gears are found in agricultural equipment, including tractors, harvesters, and irrigation systems.

- Power Generation: Bevel gears are essential in power generation systems, such as turbines and generators.

- Robotics and Automation: Forging bevel gears play a vital role in robotic systems and automated machinery.

Installation and Maintenance of Forging Bevel Gears

Installation:

- Proper Alignment: Ensure accurate alignment of the bevel gears to prevent premature wear and failure.

- Lubrication: Apply appropriate lubrication to reduce friction and wear between the gear teeth.

- Mounting Bolts: Use the correct mounting bolts and ensure proper torque for secure attachment.

- Inspection: Thoroughly inspect the gears and mating components before installation to identify any defects or damage.

Maintenance:

- Lubrication: Regularly lubricate the bevel gears to maintain optimal performance and prevent premature wear.

- Cleaning: Keep the gears clean and free from debris or contaminants that can affect their functionality.

- Inspection: Periodically inspect the gears for wear, pitting, or damage, and take necessary actions for repair or replacement.

- Replacements: Replace worn or damaged gears to ensure safe and reliable operation of the equipment.

- Gearbox Maintenance: Properly maintain the gearbox housing and seals to prevent leakage and ensure efficient gear operation.

- Load Monitoring: Monitor the load and operating conditions to avoid overloading and potential gear failure.

- Training and Expertise: Equip maintenance personnel with the necessary training and expertise to handle bevel gear maintenance effectively.

- Record-Keeping: Maintain comprehensive records of maintenance activities, including inspections, lubrication schedules, and replacements.

Selecting the Right Forging Bevel Gear

To select the appropriate forging bevel gear for a specific application, consider the following factors:

- Application Requirements: Understand the operational conditions and torque requirements of the application.

- Design and Specifications: Determine the required gear size, tooth profile, and other design parameters.

- Material Selection: Select a suitable material based on factors such as strength, corrosion resistance, and temperature resistance.

- Quality and Reliability: Choose a reputable manufacturer that ensures high-quality and reliable gear production.

- Load-Carrying Capacity: Consider the maximum load the gear needs to handle without failure.

- Efficiency and Performance: Evaluate the gear's efficiency and its impact on the overall system performance.

- Customization and Adaptability: Assess whether the gear can be customized to meet specific application requirements.

- Cost Considerations: Balance the cost of the gear with its performance and longevity.

About Shaoxing Chaoli

Shaoxing Chaoli is a professional manufacturer of gears in China. With a wide range of gear products, including forging bevel gears, worm gears, spiral bevel gears, helical gears, spur gears, plastic gears, and metric gear racks, Shaoxing Chaoli serves various industries globally.

Our products are exported to different countries such as Spain, the Netherlands, the United States, South Korea, Turkey, and Russia. We aim to assist customers in developing new products and solving technical and quality issues. We are committed to meeting user needs with high-quality products, fair prices, and excellent services.

In summary, our guiding principles are quality first, timely delivery, and credit first. We sincerely treat every business partner and warmly welcome collaboration to create mutual success. Additionally, Shaoxing Chaoli offers a wide range of other gear products to cater to specific customization requirements.

Shaoxing Chaoli has a dedicated team of engineers and technicians, and our production facilities are equipped with advanced precision measuring instruments and monitoring systems. With considerable competitiveness in the industry, Shaoxing Chaoli has established long-term partnerships with domestic steel rolling mills, shipyards, precision machine tool factories, and distribution companies. Our products are also exported to Western Europe, the Middle East, Southeast Asia, and other regions.

“Quality first, timely delivery, and credit first.”