Forging Bevel Gear Load Capacity Validation Procedures

Introduction

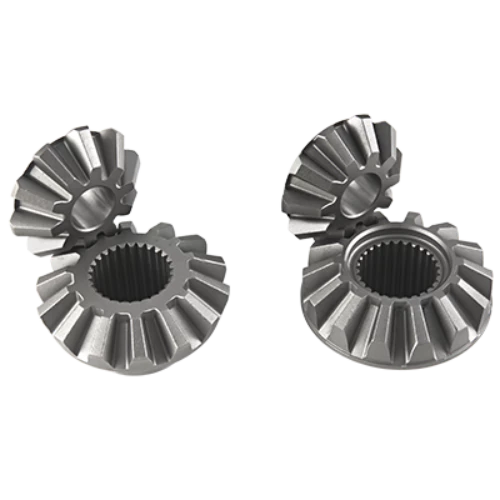

Forging bevel gears are a type of bevel gears that are manufactured through the forging process. Forging involves shaping metal through the application of localized compressive forces, typically using a die or hammer. In the case of bevel gears, the forging process is used to form the gear teeth and create the desired gear geometry.

Advantages of Forging Bevel Gears

1. High Strength

Forging bevel gears have superior strength compared to other types of gears. The forging process aligns the metal grain structure, resulting in enhanced load-carrying capacity and improved durability.

2. Improved Fatigue Resistance

The controlled grain flow achieved through forging enhances the fatigue resistance of bevel gears, allowing them to withstand repetitive loading and prolonged operation without failure.

Working Principle

Forging bevel gears operate based on the fundamental principles of gear mechanisms. They consist of two intersecting shafts, each with a conically shaped gear (bevel gear) mounted on it. The teeth of the bevel gears are designed to have a specific tooth profile, such as straight, spiral, or hypoid, depending on the application requirements.

Applications

1. Automotive Industry

Forging bevel gears are used in automotive transmissions and differential systems, providing reliable power transmission and efficient torque transfer.

Installation and Maintenance

Installation

1. Proper Alignment: Precise alignment of the bevel gears is crucial for optimal performance and longevity.

Maintenance

1. Lubrication: Regular lubrication of the bevel gears ensures smooth operation and reduces wear.

Selecting the Appropriate Forging Bevel Gear

1. Application Requirements

Consider the specific requirements of the application, such as load capacity, speed, and environmental conditions, to select the suitable forging bevel gear.

Shaoxing Chaoli – Professional Forging Bevel Gear Manufacturer

Shaoxing Chaoli is a professional manufacturer of gears in China. With a complete set of strict quality management systems and advanced production monitoring systems, Shaoxing Chaoli produces high-quality forging bevel gears that meet international standards.

Our products are exported to different countries and we strive to help customers develop new products and solve technical and quality problems. With a commitment to quality, timely delivery, and excellent service, Shaoxing Chaoli welcomes cooperation with business partners to create brilliance together.

In addition to forging bevel gears, Shaoxing Chaoli also offers a wide range of other gear products, including worm gears, spiral bevel gears, helical gears, spur gears, plastic gears, and metric gear racks. Customized products are also available upon inquiry.