Forging Bevel Gear Material Property Characterization

Introduction

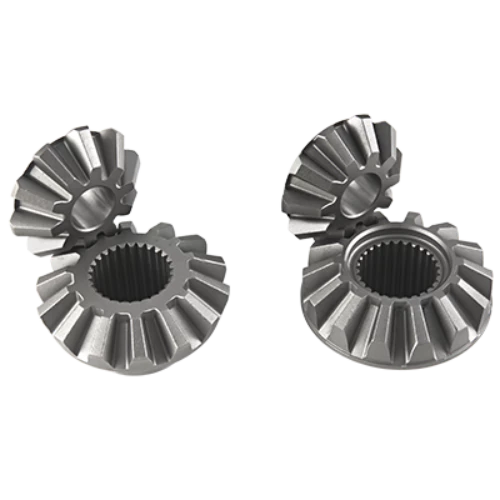

Forging bevel gears are a type of bevel gears that are manufactured through the forging process. Forging involves shaping metal through the application of localized compressive forces, typically using a die or hammer. In the case of bevel gears, the forging process is used to form the gear teeth and create the desired gear geometry.

Advantages

1. High Strength

Forging bevel gears exhibit high strength due to the deformation and alignment of the metal grains during the forging process. This results in improved load-carrying capacity and durability.

2. Improved Fatigue Resistance

The forging process enhances the fatigue resistance of bevel gears by eliminating internal defects and improving the material's microstructure. This allows the gears to withstand repeated loading without failure.

3. Precise Gear Tooth Geometry

Forging enables the production of bevel gears with precise gear tooth geometry, ensuring smooth operation and efficient power transmission.

4. Cost-Effectiveness

Forging bevel gears offer cost-effectiveness in terms of production efficiency, material utilization, and overall performance. The high-quality and long-lasting nature of forged gears also reduces the need for frequent replacements and maintenance.

5. Versatility in Material Selection

Forging allows for the use of a wide range of materials, including steel, stainless steel, and non-ferrous alloys, providing flexibility in meeting specific application requirements.

6. Enhanced Structural Integrity

The forging process imparts superior structural integrity to bevel gears by aligning the metal grains and eliminating internal defects. This results in improved resistance to wear, deformation, and other forms of mechanical stress.

7. Tailored Mechanical Properties

Forging can be used to control and enhance the mechanical properties of bevel gears, such as hardness, toughness, and wear resistance. This enables the gears to perform optimally in various operating conditions.

8. Reduced Lead Time

The forging process allows for the efficient and rapid production of bevel gears, reducing lead time and ensuring timely delivery of products.

9. Environmental Sustainability

Forging is a sustainable manufacturing process that minimizes material waste and energy consumption. It also contributes to the longevity and recyclability of bevel gears.

Working Principle

Forging bevel gears operate based on the fundamental principles of gear mechanisms. They consist of two intersecting shafts, each with a conically shaped gear (bevel gear) mounted on it. The teeth of the bevel gears are designed to have a specific tooth profile, such as straight, spiral, or hypoid, depending on the application requirements.

When the input shaft rotates, the engagement of the teeth of the bevel gears causes a transfer of rotational motion and torque to the output shaft. The contact between the mating teeth ensures power transmission while maintaining proper alignment and smooth operation.

Applications

1. Automotive Industry

Forging bevel gears find extensive use in automotive applications, such as transmission systems, differential gears, and steering mechanisms. Their high strength and precise tooth geometry contribute to the efficient and reliable performance of vehicles.

2. Industrial Machinery

In industrial machinery, forging bevel gears are utilized in various equipment, including gearboxes, machine tools, and conveyors. Their durability and load-carrying capacity make them ideal for heavy-duty applications.

3. Aerospace and Defense

The aerospace and defense sectors employ forging bevel gears in critical applications, such as aircraft engines, rotor systems, and military vehicles. The gears' high strength, reliability, and fatigue resistance are crucial for ensuring safe and efficient operations.

4. Renewable Energy

Forging bevel gears play a significant role in renewable energy systems, such as wind turbines and hydroelectric generators. Their ability to withstand high loads and harsh environmental conditions makes them suitable for power generation applications.

5. Marine and Shipbuilding

In the marine and shipbuilding industry, forging bevel gears are used in propulsion systems, steering mechanisms, and winches. Their resilience to corrosion and high strength are essential for marine applications.

6. Agricultural Machinery

Agricultural machinery, including tractors and harvesters, relies on forging bevel gears for power transmission and torque conversion. The gears' robustness and efficiency contribute to the productivity of agricultural operations.

7. Power Generation

In power generation plants, forging bevel gears are employed in turbines, generators, and other critical components. Their ability to handle high speeds, loads, and temperature variations is vital for efficient and reliable power generation.

8. Robotics and Automation

Forging bevel gears are utilized in robotics and automation systems for precise motion control and power transmission. Their high accuracy and durability enable smooth and efficient robotic operations.

Installation and Maintenance

Installation:

- Proper Alignment

- Lubrication

- Mounting Bolts

- Inspection

Maintenance:

- Lubrication

- Cleaning

- Inspection

- Replacements

- Gearbox Maintenance

- Load Monitoring

- Training and Expertise

- Record-Keeping

How to Select the Right Forging Bevel Gear

- Application Requirements

- Design and Specifications

- Material Selection

- Quality and Reliability

- Load-Carrying Capacity

- Efficiency and Performance

- Customization and Adaptability

- Cost Considerations

Shaoxing Chaoli: Leading Manufacturer of Forging Bevel Gears

Shaoxing Chaoli is a professional manufacturer of gears in China. Our products are exported to different countries such as Spain, the Netherlands, the United States, South Korea, Turkey, and Russia. We strive to help customers develop new products and solve technical and quality problems by providing high-quality products, fair prices, and perfect services. We adhere to the principles of quality first, timely delivery, and credit first, treating every business partner sincerely. We wholeheartedly welcome friends from the business community to cooperate with us and create brilliance together.

In addition to forging bevel gears, Shaoxing Chaoli also offers a wide range of gear products, including worm gears, spiral bevel gears, helical gears, spur gears, plastic gears, and metric gear racks. Customers are welcome to inquire about customized products.

Shaoxing Chaoli boasts hundreds of employees, including many engineers, and has fixed assets of 20 million yuan. Our annual output value reaches 50 million yuan. We have a complete set of strict quality management systems and utilize precision measuring instruments such as optical projectors and 16 full-process production monitoring systems. These factors contribute to our considerable competitiveness in the industry.