Description

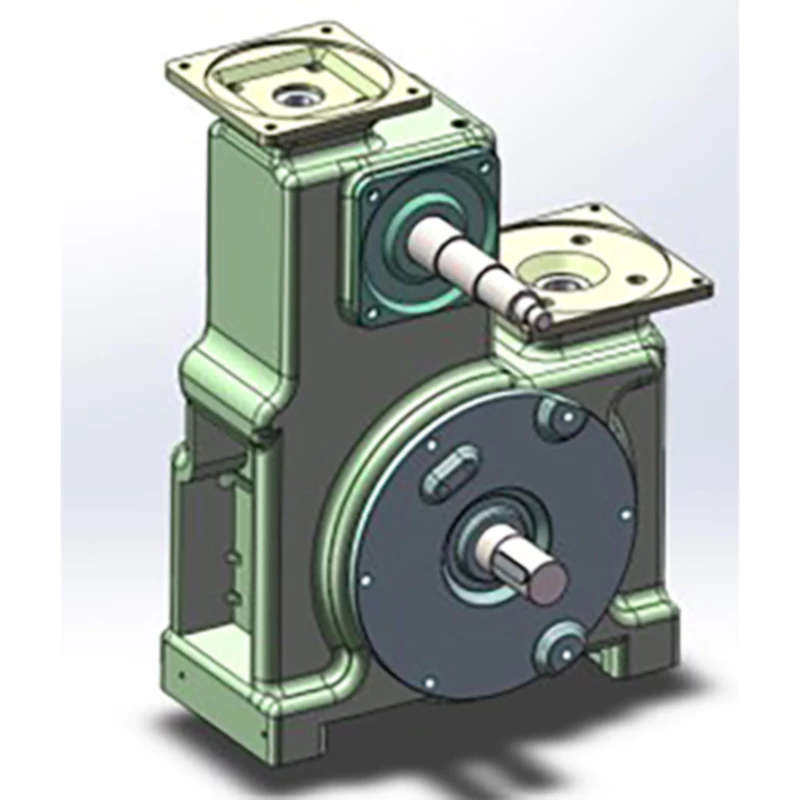

Dual Input Terminal Non Standard Reducer Worm Helical Gearbox For Heavy equipment

A Non Standard Gearbox is a gear transmission device that is custom-designed and manufactured to meet specific application requirements. They can have different sizes, gear configurations, gear ratios, and torque capacities to suit various engineering and mechanical applications.

Product Advantages and Features

- Custom Design: Non Standard Gearboxes are custom-designed to meet specific application requirements, accommodating unique engineering and mechanical demands.

- Unique Size and Configuration: The size and configuration of Non Standard Gearboxes can be optimized to meet the application's requirements, achieving better adaptability and performance.

- High Torque Capacity: These gearboxes are typically able to withstand high torque and loads, making them suitable for applications requiring high power transmission.

- High Precision and Reliability: Non Standard Gearboxes are often manufactured and assembled with precision to ensure high accuracy and reliable operation.

- Multiple Gear Ratios Selection: Non Standard Gearboxes can provide different gear ratios according to the application's requirements to meet specific speed and torque requirements.

Applications

- Industrial Manufacturing and Automation: Non Standard Gearboxes are commonly used in various industrial machinery and equipment such as lathes, mixers, conveyors, compressors, and pumps. They are used to achieve high torque transmission and precise motion control to meet complex manufacturing and automation requirements.

- Food and Beverage Processing: In food and beverage production processes, Non Standard Gearboxes can be used in equipment such as mixers, blenders, conveyors, etc., to ensure efficient production and processing.

- Packaging Industry: Non Standard Gearboxes play an important role in packaging machinery. They are used to control conveyor belts, rotating mechanisms, sealing devices, ensuring accurate and efficient packaging of products.

- Power Transmission and Generation: Non Standard Gearboxes are widely used in the power transmission and generation field. They are used in equipment such as wind turbines, hydroelectric generators, and generators to achieve efficient energy conversion and transmission.

- Metallurgy and Mining: Non Standard Gearboxes are used in metallurgy and mining to drive crushers, mills, mixing equipment, etc. They can withstand the working requirements of high loads and harsh environmental conditions.

- Ports and Logistics: In ports and logistics, Non Standard Gearboxes can be used in equipment such as cranes, conveyors, stackers, etc., to achieve efficient handling and transportation of goods.

- Automotive Industry: Non Standard Gearboxes are widely used in automotive production and testing equipment. They are used to drive transmission systems, test benches, and mechanical assembly lines.

- Medical Equipment: Non Standard Gearboxes have important applications in medical equipment such as surgical robots, CT scanners, radiation therapy equipment, etc.

- Oil and Gas Industry: In the oil and gas extraction and processing process, Non Standard Gearboxes are used in equipment such as pumps, compressors, centrifuges, etc.

- Special Engineering and Customized Machinery: Due to the custom design characteristics of Non Standard Gearboxes, they are widely used in various special engineering and customized machinery projects to meet specific technical and functional requirements.

Installation and Maintenance

Installation: When installing Non Standard Gearboxes, it is necessary to follow the manufacturer's installation guide. Ensure proper alignment of the gearbox and related equipment and use appropriate fasteners to secure them.

Lubrication: Regularly check and replace the lubricating oil to ensure that the gears and bearings are adequately lubricated. Follow the manufacturer's recommendations and the prescribed lubrication cycle.

Inspection and Maintenance: Regularly inspect the gearbox for wear, loose connections, and other potential issues. If any abnormalities are detected, take timely repair measures, such as replacing worn parts.

Cleaning: Keep the gearbox and surrounding environment clean to prevent the accumulation of dust, dirt, and impurities.

Regular Maintenance: Follow the manufacturer's provided regular maintenance plan and recommendations, including cleaning, lubrication, and inspection.

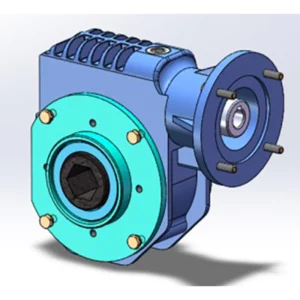

Motors and Gearboxes

Motor and gearbox are closely related, as the motor is the power source that drives the gearbox to transmit power to the driven equipment. A suitable motor should be matched with the gearbox to achieve optimal performance in the application.

About Shaoxing Chaoli Machinery Co., Ltd

Shaoxing Chaoli Machinery Co., Ltd is a comprehensive transmission equipment manufacturing enterprise integrating gearbox research and development, manufacturing, and sales. With over 20 years of experience in gearbox design, production, and sales, we have served customers covering Europe, America, Africa, Asia, etc., and received unanimous praise in the market.

Shaoxing Chaoli has introduced advanced production equipment and testing equipment at home and abroad, employing industry professionals to conduct innovative research and development and manufacturing. We use standardized production management methods to strictly control every aspect of gearbox production, providing customers with high-quality, high-efficiency, and high-stability products. Our R&D center was also established to further increase research and innovation in the transmission field, dedicated to making transmission more effective and reliable!

Shaoxing Chaoli's main products include SJMRV series worm gear reducer, XRV car washing machine special reducer, SJGV series gear reducer, SJRT series solar reducer, SJBD series harmonic reducer, as well as various non-standard reducers. Our products are widely used in equipment industry, food industry, car washing industry, packaging industry, transmission industry, automation industry, solar industry, etc., and are deeply welcomed and trusted by customers.

Shaoxing Chaoli is a professional company that produces non-standard gearboxes, with a complete range of products. As a precision mechanical transmission device, the gearbox has a wide range of applications in various fields of the national economy and national defense industry. The product series developed by Shaoxing Chaoli can serve the food industry, packaging industry, automation industry, equipment industry, transmission industry, solar industry, car washing industry, and many other fields. Shaoxing Chaoli will continue to increase product research and investment to enrich the gearbox product series.

FAQs

- What is a Non Standard Gearbox?

- What are the advantages of Non Standard Gearboxes?

- What are the applications of Non Standard Gearboxes?

- How should I install and maintain Non Standard Gearboxes?

- What is the relationship between motors and gearboxes?

A Non Standard Gearbox is a gear transmission device that is custom-designed and manufactured to meet specific application requirements.

The advantages of Non Standard Gearboxes include custom design, unique size and configuration, high torque capacity, high precision and reliability, and multiple gear ratios selection.

The applications of Non Standard Gearboxes include industrial manufacturing and automation, food and beverage processing, packaging industry, power transmission and generation, metallurgy and mining, ports and logistics, automotive industry, medical equipment, oil and gas industry, and special engineering and customized machinery.

When installing Non Standard Gearboxes, it is necessary to follow the manufacturer's installation guide. Regularly check and replace the lubricating oil, inspect the gearbox for wear, loose connections, and other potential issues, keep the gearbox and surrounding environment clean, and follow the manufacturer's provided regular maintenance plan and recommendations.

The motor is the power source that drives the gearbox to transmit power to the driven equipment. A suitable motor should be matched with the gearbox to achieve optimal performance in the application.

Choose Shaoxing Chaoli Machinery Co., Ltd, and let us help you with your gearbox needs with our rich experience, advanced production equipment, skilled technical team, and excellent after-sales service. We provide high-quality, efficient, and reliable gearbox solutions to meet your specific application requirements. Contact us now!