Description

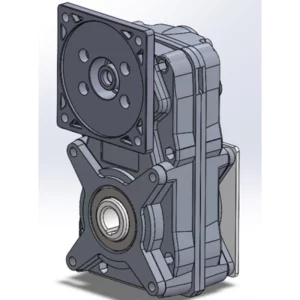

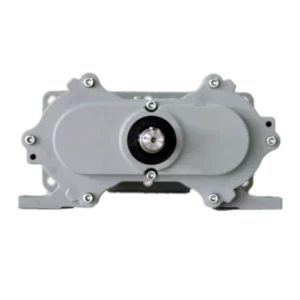

Dual Lead Dual Input Non Standard Gear Motor Reducer Worm Gearbox For Sale 0.06KW 0.09KW 0.12KW 0.18KW 0.25KW 0.37KW

A Non Standard Gearbox is a gear transmission device that is custom-designed and manufactured according to specific application requirements. They can have different sizes, gear configurations, gear ratios, and torque capacities to suit various engineering and mechanical applications.

Product Advantages and Features

- Custom Design: Non Standard Gearboxes are designed and manufactured according to specific application requirements to meet special engineering and mechanical requirements.

- Unique Size and Configuration: The size and configuration of Non Standard Gearboxes can be optimized according to the requirements of the application to achieve better adaptability and performance.

- High Torque Capacity: These gearboxes can typically withstand high torque and loads, making them suitable for applications that require high power transmission.

- High Precision and Reliability: Non Standard Gearboxes typically use precision manufacturing and assembly to ensure high precision and reliable operation.

- Multiple Gear Ratios to choose from: Non Standard Gearboxes can provide different gear ratios according to the requirements of the application to meet specific speed and torque requirements.

Applications

Non Standard Gearboxes are commonly used in various industrial machinery and equipment such as machine tools, mixers, conveyors, compressors, pumps, etc. They are used to achieve high torque transmission and precise motion control to meet complex manufacturing and automation requirements.

Other applications include:

- Food and Beverage Processing

- Packaging Industry

- Power Transmission and Generation

- Metallurgy and Mining

- Port and Logistics

- Automobile Industry

- Medical Equipment

- Oil and Gas Industry

- Special Engineering and Custom Machinery

Installation and Maintenance

When installing Non Standard Gearboxes, it is necessary to follow the installation guide provided by the manufacturer. Ensure correct alignment of the gearbox and related equipment and use appropriate fasteners for fixing.

Other maintenance tips include:

- Lubrication: Regularly check and replace lubricating oil to ensure gears and bearings are adequately lubricated. Follow the manufacturer's recommendations and the prescribed lubrication schedule.

- Inspection and Maintenance: Regularly inspect the gearbox for wear, loose connections, and other potential issues. If any abnormalities are found, take timely repair measures such as replacing worn parts.

- Cleaning: Keep the gearbox and surrounding environment clean to prevent the accumulation of dust, dirt, and impurities.

- Regular Maintenance: Follow the manufacturer's recommended periodic maintenance plan, including cleaning, lubrication, and inspection.

Motor and Gearbox Matching

A motor and gearbox work together to provide efficient power transmission. The motor is responsible for providing the power, while the gearbox is responsible for transmitting that power to the desired output.

About Shaoxing Chaoli Machinery Co., Ltd

Shaoxing Chaoli Machinery Co., Ltd is a comprehensive transmission equipment manufacturing enterprise that integrates gearbox research and development, manufacturing, and sales. With over 20 years of experience in gearbox design, production, and sales, Chaoli serves customers in Europe, America, Africa, Asia, and other regions and has received unanimous praise from the market.

Chaoli has introduced advanced production and testing equipment from both domestic and international markets and employs industry professionals for innovative research and development and manufacturing. The company uses standardized production management to strictly control every aspect of gearbox production and has been providing customers with high-quality, high-efficiency, and stable products for many years.

Chaoli has established a research and development center to further increase research and innovation in the transmission field and is committed to providing transmission component solutions that are more effective and reliable. Currently, Chaoli's main products include the SJMRV series of worm gearboxes, XRV series of car wash machine special gearboxes, SJGV series of gear reducers, SJRT series of solar energy gearboxes, SJBD series of harmonic reducers, and various non-standard gearboxes. These products are widely used in various industries such as equipment, food, car washing, packaging, transmission, automation, solar energy, etc. and are highly welcomed and trusted by customers.

FAQ

1. What is a Non Standard Gearbox?

A Non Standard Gearbox is a gear transmission device that is custom-designed and manufactured according to specific application requirements. They can have different sizes, gear configurations, gear ratios, and torque capacities to suit various engineering and mechanical applications.

2. What are the advantages of Non Standard Gearboxes?

- Custom Design: Non Standard Gearboxes are designed and manufactured according to specific application requirements to meet special engineering and mechanical requirements.

- Unique Size and Configuration: The size and configuration of Non Standard Gearboxes can be optimized according to the requirements of the application to achieve better adaptability and performance.

- High Torque Capacity: These gearboxes can typically withstand high torque and loads, making them suitable for applications that require high power transmission.

- High Precision and Reliability: Non Standard Gearboxes typically use precision manufacturing and assembly to ensure high precision and reliable operation.

- Multiple Gear Ratios to choose from: Non Standard Gearboxes can provide different gear ratios according to the requirements of the application to meet specific speed and torque requirements.

3. What are the applications of Non Standard Gearboxes?

Non Standard Gearboxes are commonly used in various industrial machinery and equipment such as machine tools, mixers, conveyors, compressors, pumps, etc. They are used to achieve high torque transmission and precise motion control to meet complex manufacturing and automation requirements. Other applications include food and beverage processing, packaging industry, power transmission and generation, metallurgy and mining, port and logistics, automobile industry, medical equipment, oil and gas industry, special engineering and custom machinery.

4. How do I install and maintain a Non Standard Gearbox?

When installing Non Standard Gearboxes, it is necessary to follow the installation guide provided by the manufacturer. Ensure correct alignment of the gearbox and related equipment and use appropriate fasteners for fixing. Other maintenance tips include regular lubrication, inspection and maintenance, cleaning, and regular maintenance as per the manufacturer's recommendations.

5. What is the relationship between a motor and gearbox?

A motor and gearbox work together to provide efficient power transmission. The motor is responsible for providing the power, while the gearbox is responsible for transmitting that power to the desired output.