What are the advantages of forging bevel gears?

1. High Strength

Forging bevel gears offer exceptional strength due to the forging process, which enhances the metal's structural integrity and eliminates internal defects.

2. Improved Fatigue Resistance

Compared to other manufacturing methods, forging creates bevel gears with superior fatigue resistance, ensuring reliable performance even under heavy loads and cyclic stress.

3. Precise Gear Tooth Geometry

The forging process enables precise control over the gear tooth geometry, resulting in accurate and efficient power transmission with minimal noise and vibration.

4. Cost-Effectiveness

Forging bevel gears offer cost-effectiveness by reducing material waste, minimizing machining requirements, and providing long-lasting performance, reducing the need for frequent replacements.

5. Versatility in Material Selection

With forging, bevel gears can be manufactured from a wide range of materials, including alloy steels, stainless steels, and non-ferrous metals, allowing for optimal material selection based on specific application requirements.

6. Enhanced Structural Integrity

The forging process enhances the internal grain structure of the gear, resulting in improved mechanical properties, such as higher toughness, hardness, and wear resistance, ensuring long-term durability.

7. Tailored Mechanical Properties

Forging allows for the customization of mechanical properties, such as hardness and strength, to meet the specific demands of different applications, ensuring optimal performance in various operating conditions.

8. Reduced Lead Time

Forging bevel gears have shorter lead times compared to other manufacturing methods, allowing for faster production and delivery of gears, minimizing downtime and improving overall productivity.

9. Environmental Sustainability

Forging is a sustainable manufacturing process that generates less waste and requires less energy compared to other methods, making forging bevel gears an eco-friendly choice.

How do forging bevel gears work?

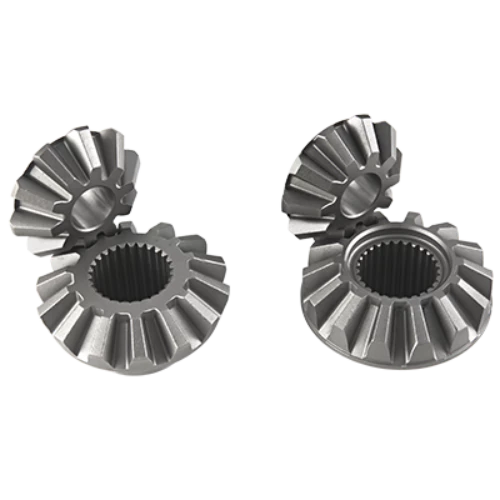

Forging bevel gears operate based on the fundamental principles of gear mechanisms. They consist of two intersecting shafts, each with a conically shaped gear (bevel gear) mounted on it. The teeth of the bevel gears are designed to have a specific tooth profile, such as straight, spiral, or hypoid, depending on the application requirements.

When the input shaft rotates, the engagement of the teeth of the bevel gears causes a transfer of rotational motion and torque to the output shaft. The contact between the mating teeth ensures power transmission while maintaining proper alignment and smooth operation.

Applications of forging bevel gears

1. Automotive Industry

Forging bevel gears find extensive use in automotive applications, such as differential systems, steering mechanisms, and transmission systems, ensuring smooth and efficient power transmission.

2. Industrial Machinery

Industrial machinery, including heavy-duty equipment and machinery used in manufacturing processes, rely on forging bevel gears for reliable and precise power transmission.

3. Aerospace and Defense

The aerospace and defense industry utilizes forging bevel gears in various applications, such as aircraft engines, helicopter transmissions, and military vehicles, ensuring robust performance and safety.

4. Renewable Energy

Forging bevel gears play a crucial role in renewable energy systems, such as wind turbines and solar tracking systems, ensuring efficient and reliable power generation.

5. Marine and Shipbuilding

In the marine and shipbuilding industry, forging bevel gears are used in propulsion systems, steering mechanisms, and various other applications, providing reliable and durable performance in harsh marine environments.

6. Agricultural Machinery

Agricultural machinery, including tractors and harvesters, rely on forging bevel gears for efficient power transmission, ensuring optimal performance in demanding agricultural operations.

7. Power Generation

In power generation facilities, forging bevel gears are employed in turbines, generators, and other critical equipment, enabling efficient and reliable power generation.

8. Robotics and Automation

Forging bevel gears are crucial components in robotics and automation systems, facilitating precise and controlled movement in various applications, ranging from industrial robots to automated assembly lines.

Installation and Maintenance

Installation:

- Proper Alignment

- Lubrication

- Mounting Bolts

- Inspection

Maintenance:

- Lubrication

- Cleaning

- Inspection

- Replacements

- Gearbox Maintenance

- Load Monitoring

- Training and Expertise

- Record-Keeping

How to select the right Forging Bevel Gear?

- Application Requirements

- Design and Specifications

- Material Selection

- Quality and Reliability

- Load-Carrying Capacity

- Efficiency and Performance

- Customization and Adaptability

- Cost Considerations

About Shaoxing Chaoli

Shaoxing Chaoli is a professional manufacturer of gears in China. With a strong commitment to quality, timely delivery, and customer satisfaction, Shaoxing Chaoli has earned a reputation as a reliable supplier in the industry.

Our products are exported to different countries such as Spain, the Netherlands, the United States, South Korea, Turkey, and Russia. We strive to assist customers in developing new products and solving technical and quality issues. We offer high-quality products, fair prices, and excellent services to meet the needs of our clients.

Shaoxing Chaoli specializes in various gear products, including Worm Gear, spiral bevel gear, Helical Gear, Spur Gear, plastic gear, metric gear rack, and more. We welcome customer inquiries for customized products.

Shaoxing Chaoli currently has hundreds of employees, including engineers, and possesses advanced facilities and equipment. With a complete quality management system and precision measuring instruments, we ensure the highest standards of quality and competitiveness in the industry.

In conclusion, Shaoxing Chaoli is dedicated to providing superior products and services. We sincerely welcome business partners to cooperate with us for mutual development and success.