What are the considerations for material traceability in forging bevel gears?

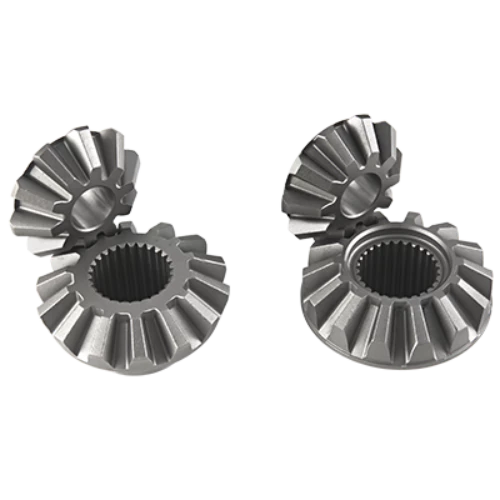

Forging bevel gears are a type of bevel gears that are manufactured through the forging process. Forging involves shaping metal through the application of localized compressive forces, typically using a die or hammer. In the case of bevel gears, the forging process is used to form the gear teeth and create the desired gear geometry.

Advantages of Forging Bevel Gears

High Strength

High Strength- Improved Fatigue Resistance

- Precise Gear Tooth Geometry

- Cost-Effectiveness

- Versatility in Material Selection

- Enhanced Structural Integrity

- Tailored Mechanical Properties

- Reduced Lead Time

- Environmental Sustainability

Working Principles of Forging Bevel Gears

Forging bevel gears operate based on the fundamental principles of gear mechanisms. They consist of two intersecting shafts, each with a conically shaped gear (bevel gear) mounted on it. The teeth of the bevel gears are designed to have a specific tooth profile, such as straight, spiral, or hypoid, depending on the application requirements.

Applications of Forging Bevel Gears

Forging bevel gears find applications in various industries:

- Automotive Industry

- Industrial Machinery

- Aerospace and Defense

- Renewable Energy

- Marine and Shipbuilding

- Agricultural Machinery

- Power Generation

- Robotics and Automation

Installation and Maintenance of Forging Bevel Gears

Proper installation and maintenance are crucial for the performance and longevity of forging bevel gears:

Installation:

- Proper Alignment

- Lubrication

- Mounting Bolts

- Inspection

Maintenance:

- Lubrication

- Cleaning

- Inspection

- Replacements

- Gearbox Maintenance

- Load Monitoring

- Training and Expertise

- Record-Keeping

How to Select the Right Forging Bevel Gear

When choosing a forging bevel gear, several factors should be considered:

- Application Requirements

- Design and Specifications

- Material Selection

- Quality and Reliability

- Load-Carrying Capacity

- Efficiency and Performance

- Customization and Adaptability

- Cost Considerations

Introducing Shaoxing Chaoli

Shaoxing Chaoli is a professional manufacturer of gears in China. They offer various gear products, including forging bevel gears, worm gears, spiral bevel gears, helical gears, spur gears, plastic gears, and metric gear racks.

Our products are exported to different countries such as Spain, the Netherlands, the United States, South Korea, Turkey, and Russia. We aim to help customers develop new products and solve technical and quality problems. We prioritize high-quality products, fair prices, and perfect services. We treat every business partner sincerely and welcome cooperation to create brilliance together.

Shaoxing Chaoli has a strong presence in the industry, with considerable competitiveness. The company has a complete set of strict quality management systems and is equipped with precision measuring instruments such as optical projectors and full-process production monitoring systems.

For more information, please visit https://media.epind.top/wp-content/uploads/2024/04/Stainless-Steel-Bevel-Gears-factory1.webp, https://media.epind.top/wp-content/uploads/2024/04/Stainless-Steel-Bevel-Gears-factory2.webp, and https://media.epind.top/wp-content/uploads/2024/04/Stainless-Steel-Bevel-Gears-factory3.webp.