Description

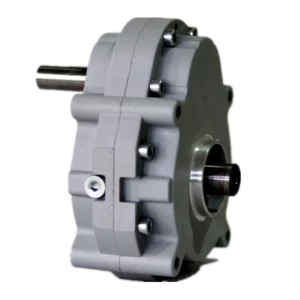

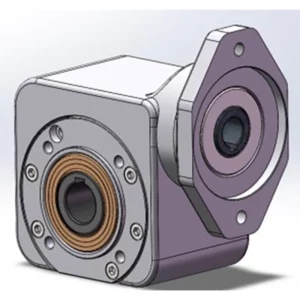

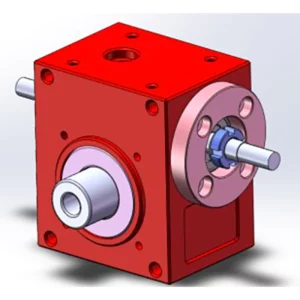

1.5KW 2.2KW 3KW 4KW 5.5KW 7.5KW 12KW 15KW Fully Self-Locking Non Standard Reducer Worm Gearbox For Outdoor Environments

A Non Standard Gearbox is a customized gear transmission device designed and manufactured to meet specific application requirements. They can have different sizes, gear configurations, transmission ratios, and torque capacities to suit various engineering and mechanical applications. The following are the advantages and features of the product:

Customized Design

Non Standard Gearboxes are designed based on specific application requirements, which can meet special engineering and mechanical requirements.

Unique Size and Configuration

The size and configuration of Non Standard Gearboxes can be optimized according to application requirements to achieve better adaptability and performance.

High Torque Capacity

These gearboxes can usually withstand high torque and loads, making them suitable for applications that require high power transmission.

High Precision and Reliability

Non Standard Gearboxes usually adopt precision manufacturing and assembly to ensure high accuracy and reliable operation.

Various Transmission Ratio Options

Based on application requirements, Non Standard Gearboxes can provide different transmission ratios to meet specific speed and torque requirements.

Applications

Non Standard Gearboxes are commonly used in various industrial machinery and equipment such as machine tools, mixers, conveyors, compressors, and pumps. They are used to achieve high torque transmission and precise motion control to meet complex manufacturing and automation requirements.

Other applications include:

- Food and Beverage Processing

- Packaging Industry

- Power Transmission and Generation

- Metallurgy and Mining

- Ports and Logistics

- Automotive Industry

- Medical Equipment

- Oil and Gas Industry

- Special Engineering and Custom Machinery

Installation and Maintenance

During installation, it is important to follow the manufacturer's installation guide to ensure proper alignment of the gearbox and related equipment and to use appropriate fasteners for secure attachment. Regular maintenance such as lubrication, inspection, and cleaning is necessary to ensure the gearbox's optimal performance and longevity.

Matching Motor

Our company provides matching motors for our gearboxes. Motors and gearboxes work together to achieve efficient power transmission in various applications.

About Shaoxing Chaoli Machinery Co., Ltd

Our main products include SJMRV series worm gearboxes, XRV series car wash machine gearboxes, SJGV series gearboxes, SJRT series solar energy gearboxes, SJBD series harmonic gearboxes, and various non-standard gearboxes, which are widely used in equipment, food, packaging, transmission, automation, solar energy, and other industries.

Shaoxing Chaoli Machinery Co., Ltd always focuses on product development and investment, and we strive to enrich our gearbox product line to better serve customers' needs. We are a professional manufacturer of non-standard gearboxes, and our products have been widely recognized and trusted by customers.

FAQs

1. What is a Non Standard Gearbox?

A Non Standard Gearbox is a customized gear transmission device designed and manufactured to meet specific application requirements.

2. What are the advantages of Non Standard Gearboxes?

The advantages of Non Standard Gearboxes include customized design, unique size and configuration, high torque capacity, high precision and reliability, and various transmission ratio options.

3. What are the applications of Non Standard Gearboxes?

Non Standard Gearboxes are used in various industrial machinery and equipment, as well as in the food and beverage processing, packaging, power transmission and generation, metallurgy and mining, ports and logistics, automotive industry, medical equipment, oil and gas industry, and special engineering and custom machinery fields.

4. How do I install and maintain Non Standard Gearboxes?

During installation, follow the manufacturer's installation guide to ensure proper alignment of the gearbox and related equipment and to use appropriate fasteners for secure attachment. Regular maintenance such as lubrication, inspection, and cleaning is necessary to ensure the gearbox's optimal performance and longevity.

5. What matching motor options are available for Non Standard Gearboxes?

Our company provides matching motors for our gearboxes. Motors and gearboxes work together to achieve efficient power transmission in various applications.